Austria-based high-precision optical device developer In-Vision is collaborating with Professor Tapajyoti Das Gupta of the Indian Institute of Science-Bangalore to develop a new sub-micron 3D printer.

In-Vision and Das Gupta have teamed up with Mumbai-based 3D printer manufacturer J Group Robotics to build the 3D printer, which will be used to produce flexible, stretchable photonic devices.

Traditionally, the production of nano-scale, high-performance optical devices employs a multi-step, layered 2D lithography process. This requires the use of multiple machines in a cleanroom facility, making the process costly and limiting scalability.

It is hoped that this new 3D printer will accelerate and lower the cost of production, disrupt the semiconductor industry, and build a more resilient supply chain. Eliminating the need for a clean room, this new 3D printer simplifies the production process into one machine, creating potential for greater production scale and new applications.

Das Gupta anticipates that the 3D printer will be completed in December 2023, and expects the first sub-micron optical components to be produced in Spring 2024.

“3D printing has taken over many other manufacturing processes, the only thing left is printing in submicron resolution,” commented Das Gupta. “This technique has the potential to reduce the cost and drive drastic change in the semiconductor industry by eliminating the clean room requirement and making production much faster.”

Developing a new sub-micron 3D printer

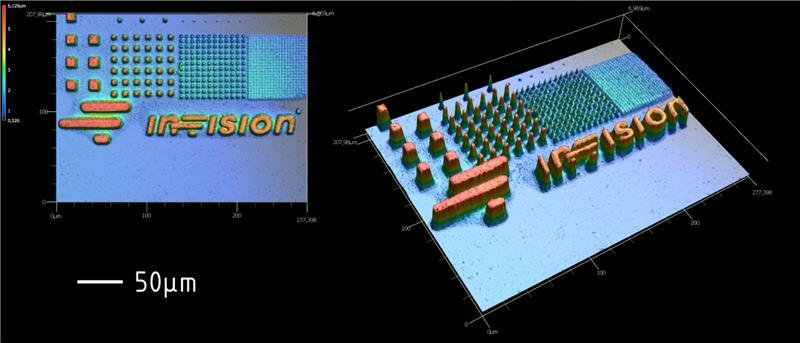

Most projectors used in DLP 3D printing are limited to one-to-two micron resolution, however Das Gupta’s work requires resolution in the sub-micron range. Therefore, In-Vision is supplying a new Light Engine projector to be incorporated into the new 3D printer. Said to be the “world’s first” sub-micron light engine for 3D printing, the projector is based on a DLP9000-Chipset with a newly designed optical path. Ultimately, this projector can achieve sub-micron resolution at a wavelength of 405 nanometers. This marks In-Vision’s first foray into sub-micron 3D printing.

“The light engine is the key component of our process, and when you get to this sub-micron level resolution, it requires much greater precision,” explained Das Gupta. “In-Vision is the only company willing to make this a reality by developing the world’s first sub-micron light engine for 3D printing.”

Thanks to funding from the Indian Ministry of Electronics & Information, Das Gupta and In-Vision have partnered with J Group Robotics to build the 3D printer. The team frequently meets to tackle technical challenges and align on the 3D printers design and specifications.

The production of this new sub-micron 3D printer meets growing demand for the production of minuscule optical components used in a range of electrical devices, such as smartphones, SLR cameras, and virtual reality devices.

Moreover, sub-micron fabrication capabilities are said to offer value in additional verticals. For instance, the technology can be leveraged to produce hydrogels and biopolymers for use in contact lenses and the semiconductor industry. Additionally, biosensors used in spectral analysis for the detection of COVID-19 and other pathogens with a low material concentration can be produced through sub-micron 3D printing.

Das Gupta has also pointed to the potential environmental benefits of this technology. “It also reduces the carbon footprint of the entire production process and could dramatically improve supply chain resiliency, allowing companies to produce and procure chips much closer to home.”

Ultra-high resolution 3D printing

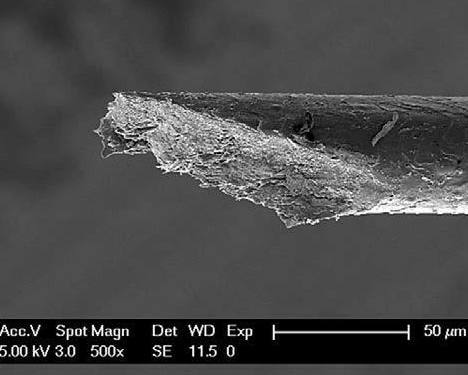

Low-micron 3D printing is not a new concept within the additive manufacturing industry. Back in 2019, French ultra-high-resolution 3D printer manufacturer Microlight3D launched the Altraspin, a 3D printer capable of producing a resolution as low as 0.2µm, 100 times smaller than the width of a human hair. The Altraspin 3D printer offers value within micro-robotics, bioengineering, and microsensor applications, and was designed to meet the growing demand for sub-micron fabrication.

Elsewhere, researchers from Stanford University conducted a study on microfabrication using additive manufacturing. The study, published in Science Advances, outlined a new approach to address multiple microfabrication issues within additive manufacturing, enabling objects to be 3D printed as small as 1.5 microns. The single-digit-micron resolution technology developed by the researchers, called micro-CLIP, allows for 50X smaller part features than commercial CLIP 3D printers, while retaining high 3D print speeds.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows an In-Vision laser microscope sample. Image via In-Vision.

Newer

BMF launches the world’s thinnest cosmetic dental veneer offering a minimally invasive treatment option

Older

Cómo Funciona una Impresora 3D

Comments (0)

Dejar una respuesta

Debe de ingresar para publicar un comentario.